System Description

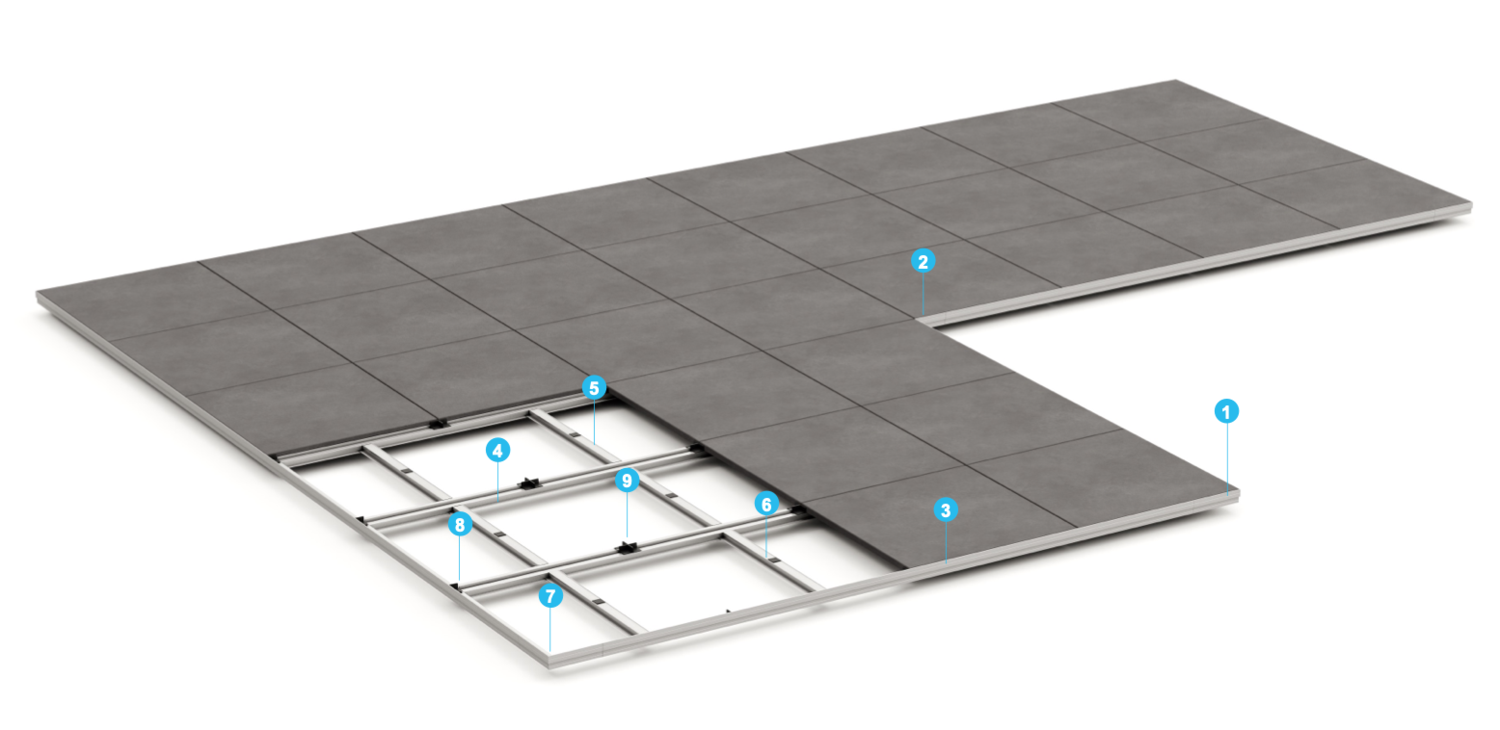

- The TALUX system is an aluminium profile system for easy, quick and economical laying of stone, ceramic and calibrated natural stone tiles as well as wood and WPC boards. There are many applications, including balconies, patios, flat roofs, swimming pool copings, roof terraces and walkways. The TALUX system can even be used for customised constructions such as stair treads or landings.

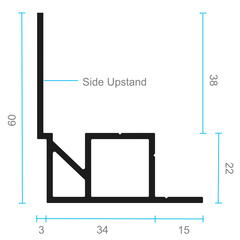

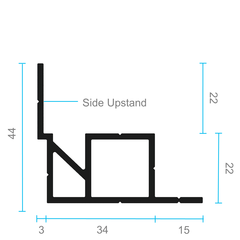

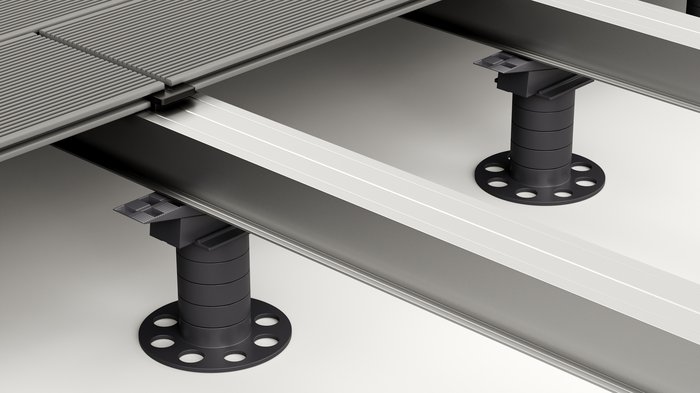

- The system is available in two profile thicknesses. The minimum assembly height (excluding covering) is 22 mm for the slim system and 64 mm for the raised system.

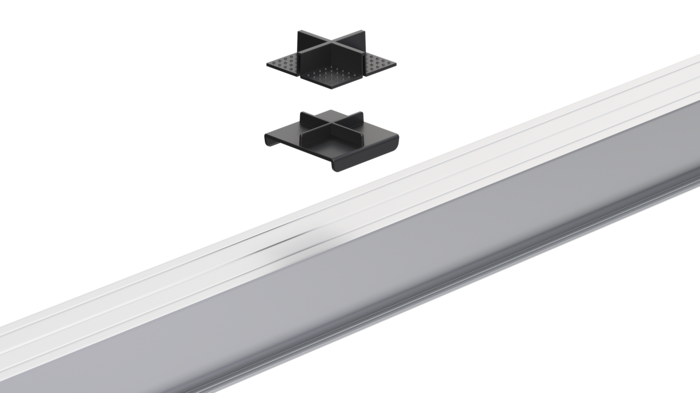

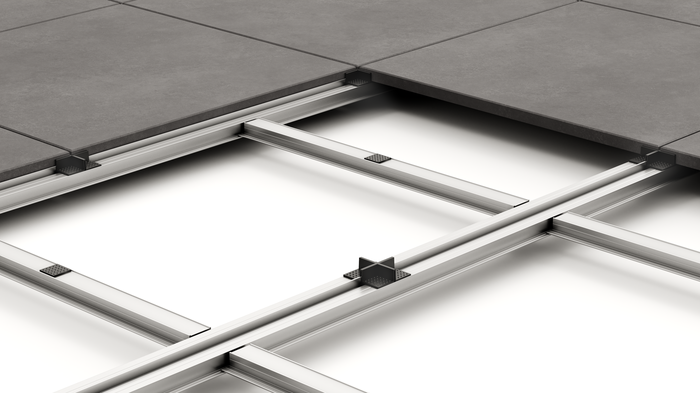

- Basically, the system consists of the edge profiles, corner modules (exterior corners, interior corners), secondary profiles, support profiles as well as the joint elements.

- The exterior and interior corners form a frame with the edge profiles that corresponds to the floor plan of the installation surface. The edge profiles are fastened to the corner modules and to each other with linear connectors.

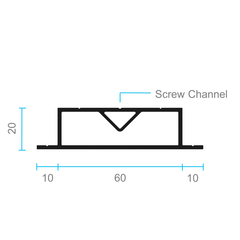

- The secondary profiles rest on the horizontal face of the edge profiles. At the joints, the profiles are spaced approx. 3-5 mm apart. For laying WPC or timber boards, the secondary profiles with screw channel allow installation with visible or invisible fastening.

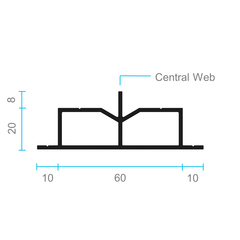

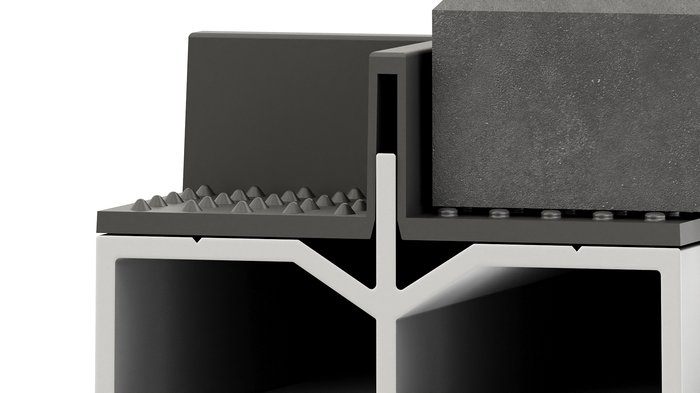

- Support profiles are used for tile widths of 600 mm and more. They are inserted together with the support pads underneath the centre of the tile to protect the large-format tiles under greater loads.

- The tile material is installed on the profile system using plastic joint elements. The dimples on the contact surface adapt to the underside of the tile, compensate for tolerances of up to approx. 1 mm and ensure that the tiles are insulated against impact sound.

- Flush panels can be fitted to the side upstand of the edge profiles, which close the system flush and imperceptible at the bottom. As an option, the panels and edge profiles are also available powder-coated in a RAL colour of your choice.

Advantages at a Glance

- Low profile heigth of 22 mm for low build-up heights

- Suitable for all tile formats

- Quick and easy assembly: time savings of up to 30% compared to conventional laying methods

- Customised, flexible system solution

- Impact sound insulated tile support

- Consistent joint pattern

- Variable joint width: 2 mm / 4 mm

Technical Data

All Talux profiles are made of high-quality aluminium material in alloy EN AW 6060 T66. Being a light metal, aluminium provides an excellent weather resistany in comparison to wood and is therefore particularily suited for outdoor installations. Our profiles are available with mill-finished surface and - for an even higher quality surface at the visible edges of the system - with a powder-coated surface in a RAL colour of your choice.

Supporting Profiles

The supporting profiles are used for ceramic tiles with a format of 600mm or wider. In combination with the suppport pads on the surface, the profiles provide for a central support of the tiles while reducing potential noise. The suppporting profiles are positioned on the horizontal support surfaces of the edge and secondary profiles.

Heigth Compensation

Our Talux rubber pads and notched wedges enable a quick and easy heigth compensation. For larger build-up heigths the Talux support feet, consisting of a base plate, spacer rings and support plate can be used. Alternatively use continuously adjustable pedestals, stripe or point foundations or rectangular paving stones.

More project images can be found in our picture gallery